Machine Guards Protect the Worker From Which of the Following

Safeguards are essential for protecting workers from these preventable injuries. The guard shall be such that it does not offer an accident hazard in itselfPoint of operation is the area on a machine where work is actually performed upon the material being processed.

Machine Guarding Safety Requirements Expert Tips Creative Safety Supply Blog

D All of the above.

. Guards are barriers which prevent access to dangerous areas. Notifying all affected employees usually machine or equipment operators or users that the machine or equipment must be shut down to perform some maintenance or servicing. The Occupational Safety and Health Administrations OSHAs requirements for machine guarding are found in 29 Code of Federal Regulations CFR 1910 Subpart O Machinery and Machine Guarding as detailed below.

D All of the above. Affix guards to the machine where possible or secure it elsewhere if for any reason attachment to the machine is not possible. Machine guarding is used to protect the machine operator and other employees in the work area from hazards created by ingoing nip points rotating parts flying chips and sparks.

Barrier guardsdevices that physically block access to hazards. To protect the operator from the hazardous moving parts of a machine and prevent injuries. Is a permanent part of the machine.

Prevent contact machine guards must provide a physical barrier that prevents the operator from having any part of hisher body in the danger zone during the machines operating cycle. Employers with hazardous machinery must apply one or more methods of machine guarding to protect the operator and other employees during operations. Be secure - workers should not be able to easily remove or tamper with the safety guard.

The Occupational Safety and Health Administration OSHA requires any machine part that could cause injury to be guarded. Movable guard - a guard connected by mechanical means eg hinges or slides to the machine frame or an adjacent fixed element. Any machine part function or.

Guard design and material will vary from machine to machine and from tool to tool. Guards and safeguarding devices are meant to accomplish two things. When this guard is open or removed the tripping mechanism andor automatic.

The purpose of machine guarding is to protect the machine operator and other employees in the work area from the hazards created by ingoing nip points rotating parts flying chips and sparks. Elion believed that new drugs could be developed to help people. Must be firmly secured to machine.

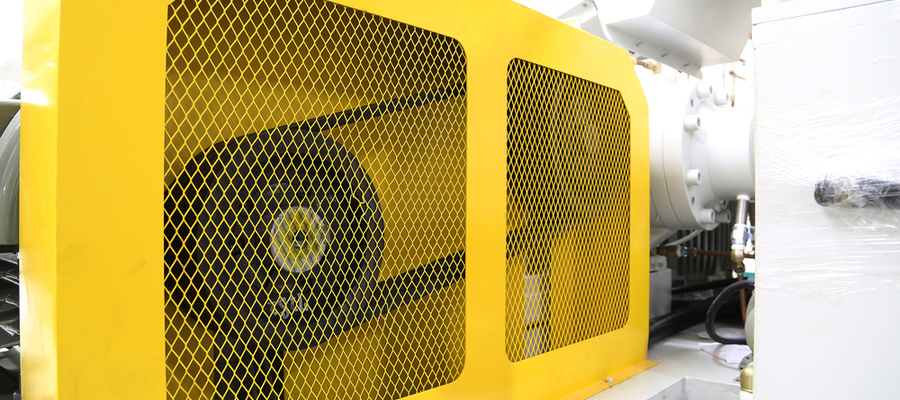

Any machine part function or process that may cause injury must be. Secondary methods of guarding machines. As shown in the photo above it may consist of nothing more than a metal fence which prevents workers from entering or touching areas that may cause injurynbspAccording to OSHA machine guarding is the first line of defense to protect.

Flying debris weld flash and other dangers make machine guarding an important component in the overall safety of a facility. Never operate a machine if a guard is missing modified or not working properly. Interlocked guard - a guard attached and monitored by the control system in such a manner that it prevents the operation of hazardous machine functions under specified conditions.

This would include hazards of concern such as. In-Running Nip Points also known as pinch points this are barrier guards light curtains and two -hand operating devices. Create no new hazards - the guard defeats its own purpose.

Which of the following explains how a guard protects workers. Elion had to work for Hitchings because she was a woman. Moving machine parts have the potential to cause severe workplace injuries such as crushed fingers or hands amputations burns or blindness.

Safeguarding Machinery Protects Workers and Saves Lives. Protect from falling objects - ensure that no objects fall into moving parts. C Restraining or removing the operators hands from the danger area.

The purpose of machine guarding is to protect the machine operator and other employees in the work area from hazards created during the machines normal operation. Prevent or detect operator contact with the point of operation or stop potentially hazardous machine motion if any part of an individuals body is within the hazardous portion of the machine. There are four general types of guards.

The fundamental purpose of machine guarding is to reduce the risk of injury to the machines operator or workers. Machine Guard Safety Rules. While this is clearly one use of machine guarding another area involves protecting workers from all types of cutting welding or grinding that can take place in tube or pipe cells.

OSHA provides the following examples of guarding methods although employers may use others. Locking out or tagging out the energy source. General Industry Machine Guarding v030117 53 Created by OTIEC Outreach Resources Workgroup Knowledge Check 4.

And to offer protection to those in the general work area from being struck by flying parts or material or inadvertently being caught by moving parts. Stops the machine when a worker enters the danger area b. It provides a barrier between the operator and the point of operation or moving parts.

Machine guarding is covered by 29 CFR Part 1910 Subpart O - Machinery and Machine Guarding and the reader must be thoroughly familiar with this regulation. The purpose of machine guarding is to protect the machine operator and other employees in the work area from hazards created by ingoing nip points rotating parts flying chips and sparks. A good rule to remember is.

Machine safeguarding helps protect workers from preventable injuries in all three areas. Elion and Hitchings developed an array variety of new drugs that were effective against leukemia autoimmune disorders urinary-tract infections gout malaria and viral herpes. Be secured in place or otherwise be tamper proof machine guards must be secure and strong so that workers are not able to bypass remove or tamper with them.

Return to Table of Contents. Ingoing nip points rotating parts reciprocating transversing andor flying chips sparks. Probe detection and safety edge devices.

Machine Guards Choose the correct answer. A Stopping the machine if any part of the body is accidentally placed in the danger area. Relieving any stored or residual energy.

Common guarding methods include. Isolating the machine or piece of equipment from its energy source. A To protect the operator from fast moving blades b To contain sawdust wood scraps and debris c To interfere with the operators ability to use the equipment d To help keep the operator safe.

Some guards also protect workers from shavings flying shards or metal sparks created by working machines. 1 Which of the following is NOT a function of machine guards. Should be made of durable material that will withstand the conditions of normal use.

Never remove or bypass a guard or other safety device. B Requiring the worker to use both hands on machine controls which keeps them out of the danger area. The point of operation of machines whose operation exposes an.

Machine Safety Machine Guarding For Warehouse And Maintenance Workers Ppt Download

Electronic Machine Safety Guards Expert Article Robson Forensic

Guards Methods Of Machine Guarding

Machine Guarding 5 Most Common Ways To Keep You Safe

Five Basic Classifications Of Machine Safeguards

Machine Guarding Basics Ehs Center

Why Is Machine Guarding Important Folding Guard

Guards Methods Of Machine Guarding

Machine Guarding Saferack S Industrial Index

Use Machine Guarding To Protect Workers From Machine Injury Better Mro

Machine Guards And Amputation Hazards Graphic Products

Four Types Of Fixed Machine Guards

Check The Importance Of Machine Guarding

Machine And Equipment Safety 1

Machine Guarding Tips Safety Blog

Machine Guards Eliminate Hazards For Employees Article The United States Army

Comments

Post a Comment